Crafting the perfect beer is a journey that combines passion, precision, and a deep understanding of the brewing process. For those eager to master the art of beer making, the principles behind each step are key to creating a beer that not only tastes exceptional but also reflects your unique style. Whether you’re a seasoned brewmaster or just beginning your journey into home brewing, mastering these fundamental beer principles is essential for consistently producing high-quality beers. From the basics of malt and hops to advanced techniques like fermentation and bottling sugar usage, this comprehensive guide will walk you through everything you need to know to craft beers that impress both your palate and your guests. Let’s dive into the world of beer principles and uncover the secrets to creating the perfect brew.

Key Takeaways

- Malted barley provides the starches that yeast converts into alcohol and carbonation.

- Water quality is crucial for flavor and safety, affecting how the beer ferments.

- Hops add bitterness and aroma, complementing the malt’s sweetness.

- Yeast is the catalyst for fermentation, transforming sugars into alcohol and CO2.

- The brewing process includes steps like milling, mashing, boiling, fermentation, conditioning, and aging.

- Various beer styles offer distinct flavor profiles, from lagers to stouts.

- Proper serving techniques, including temperature and glassware, enhance the drinking experience.

What Are the Fundamental Principles of Beer Making?

- Malted barley is the primary ingredient in most beers, providing starches that ferment into alcohol and sweetness.

- Clean water is essential for brewing, as impurities can affect flavor and safety.

- Hops are used for bitterness, aroma, and preservation, with different varieties offering unique characteristics.

- Yeast converts sugars into alcohol and carbonation, with top-fermenting yeasts commonly used in craft brewing.

- The brewing process includes boiling to extract flavors from malt and hops, then fermenting the resulting wort.

- Conditioning, such as aging or carbonating, enhances flavor and texture before bottling or serving.

- Beer can be brewed in various styles, from lagers and ales to stouts and porters, each with distinct flavor profiles.

How Beer Principles Improve the Brewing Process

The art of brewing beer is a meticulous process that relies heavily on scientific principles and craftsmanship. By applying beer principles, brewers can enhance the quality, consistency, and efficiency of their operations. Here’s how these principles contribute to improving the brewing process:

1. Water Quality and Treatment

The quality of water is crucial for brewing, as it significantly impacts the final product. Brewers use advanced water treatment methods to remove impurities and adjust the mineral content to match the beer style. Proper water management ensures a consistent brewing environment and helps maintain the desired flavor profile.

2. Malt Utilization

Malt plays a central role in beer production, and understanding its properties is essential. Brewers experiment with different malt types to achieve the desired sweetness, body, and head retention. Optimizing malt usage enhances the overall mouthfeel and flavor complexity of the beer.

3. Yeast Management

Yeast is the backbone of fermentation, and effective management ensures a healthy, active culture. Brewers monitor pH levels, temperature, and oxygenation to maximize yeast performance. Advanced techniques like pitch rates and fermentation control improve the production of desirable aromas, flavors, and esters.

4. Temperature Control

Temperature regulation during both the mashing and fermentation stages is critical. Brewers use precise controls to maintain optimal conditions, which helps extract maximum flavor compounds from the malt and yeast. Consistent temperatures reduce off-flavors and ensure a smoother fermentation process.

5. Fermmentation and Aging

Extended fermentation and aging periods allow the yeast to fully develop the beer’s character. Brewers use techniques like cold conditioning to enhance clarity and mouthfeel. This step ensures the beer ages gracefully, resulting in a more balanced and mature product.

6. Hop Utilization

Hops contribute bitterness, flavor, and aroma to beer. Brewers carefully select hop varieties and timing to achieve the desired balance. Modern techniques like dry hopping and cryo-hopping allow for more nuanced flavor profiles, enhancing the overall drinking experience.

7. Brewhouse Efficiency

Efficiency in the brewhouse reduces energy consumption and waste. Brewers implement technologies like mash tun recirculation and heat exchangers to optimize the brewing process. Improved efficiency also minimizes environmental impact and operational costs.

8. Sensory Analysis and Blending

Professional brewers conduct rigorous sensory analysis to evaluate each batch. This practice allows for fine-tuning adjustments, such as adjusting hop levels or tweaking water chemistry.Blending techniques, where different batches are combined, ensure a consistent product while exploring innovative flavor profiles.

By integrating these principles, brewers can consistently produce high-quality beers that meet the evolving preferences of consumers. The continuous refinement of brewing techniques not only enhances the taste but also supports the growth of the craft beer industry.

Essential Beer Principles Every Brewer Should Know

- Fermentation Temperature Control: Proper management of fermentation temperatures is critical for achieving the desired flavor and aroma profiles. Different beer styles often require specific temperature ranges to optimize yeast performance and sensory characteristics.

- Water Chemistry Understanding: The composition of water significantly influences the final beer’s taste. Brewers must master water hardness, mineral content, and pH levels to ensure consistent brewing results.

- Yeast Health and Management: Yeast is the backbone of fermentation. Maintaining healthy yeast cultures through proper sanitation, pitching rates, and monitoring fermentation progress is essential for high-quality beer production.

- Malt Selection and Utilization: Choosing the right malt variety and optimizing its usage is crucial for achieving the desired sweetness, body, and head retention in the finished beer.

- Hop Utilization Techniques: Hops contribute bitterness, flavor, and aroma. Brewers must understand hop alpha acids, cohumulone content, and how boiling and whirlpooling techniques affect extractable hop compounds.

- Brewing System Knowledge: Familiarity with the brewing vessel, whether it’s a traditional pot still or a modern cylindrical vessel, is essential for controlling wort distribution and ensuring consistent fermentation conditions.

- Cleaning and Sanitation Protocols: Hygiene is paramount in beer production. Establishing a robust cleaning schedule and cross-contamination prevention measures is critical to maintaining product quality and preventing off-flavors.

- Beer Style Awareness: Understanding the unique characteristics of beer styles, such as lagers, ales, stouts, and porters, allows brewers to consistently produce beers that meet market expectations and consumer preferences.

Key Beer Principles in the Brewing Process

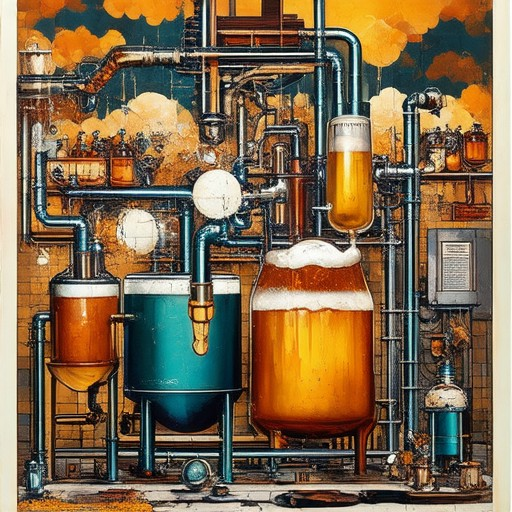

The beer-making process, often referred to as brewing, involves several key principles that ensure the creation of a quality beer. Here’s an overview of these essential components:

- Malted Barley : Malt is the backbone of beer production. Malted barley is the primary ingredient used in brewing, providing the necessary carbohydrates (starches) that yeast converts into alcohol and carbonation.

- Water : Water makes up approximately 90% of the final beer by volume. The source and treatment of water significantly impact the taste and quality of the beer, as it influences the fermentability and mouthfeel.

- Hops : Hops are a critical ingredient known for their bitter flavor and aroma. They are added during the boiling process and contribute to the beer’s balance between malt sweetness and bitterness.

- Yeast : Yeast is the catalyst for fermentation. It converts the sugars from malted barley into alcohol and carbon dioxide, which gives beer its effervescence and alcoholic content.

- Brewing Process Steps :

- Milling : The malted barley is crushed into fine particles to increase the surface area for efficient extraction.

- Mashing : Hot water is added to the crushed malt to convert starches into sugars, which are then available for yeast to consume.

- Boiling : The wort (the mixture of water and extracted sugars) is boiled, allowing hops to be added and contributing their flavors and aromas.

- Fermentation : Yeast is introduced to the wort, where it metabolizes sugars, producing alcohol and carbon dioxide.

- Conditioning : After fermentation, the beer is allowed to settle to remove solids and further refine its flavor through cold conditioning.

- Aging : The beer ages to allow flavors to meld and mellow out, enhancing its overall quality.

- Beer Chemistry : The interaction of malt, hops, and yeast creates complex chemical reactions that result in the unique flavors, aromas, and mouthfeels found in different beer styles.

- Bitterness (IBU) : The International Bitterness Unit measures the hop bitterness in beer. Higher IBU indicates a more bitter beer, while lower values suggest less bitterness.

- Alcohol by Volume (ABV) : This percentage represents the amount of alcohol in the beer relative to its total volume. It reflects the fermentation process and the amount of yeast used.

By understanding and controlling these principles, brewers can craft a wide variety of beer styles, each offering unique flavor profiles and experiences.

What Are the Fundamental Principles of Beer Making?

- Malted barley is the primary ingredient in most beers, providing starches that ferment into alcohol and sweetness.

- Clean water is essential for brewing, as impurities can affect flavor and safety.

- Hops are used for bitterness, aroma, and preservation, with different varieties offering unique characteristics.

- Yeast converts sugars into alcohol and carbonation, with top-fermenting yeasts commonly used in craft brewing.

- The brewing process includes boiling to extract flavors from malt and hops, then fermenting the resulting wort.

- Conditioning, such as aging or carbonating, enhances flavor and texture before bottling or serving.

- Beer can be brewed in various styles, from lagers and ales to stouts and porters, each with distinct flavor profiles.

What Are the Essential Principles Involved in Creating a Perfect Beer?

To craft the perfect beer, several key principles must be masterfully combined. Here’s a breakdown of the essential elements:

- Ingredient Selection :

- Malt: The heart of beer production, malted barley is the primary ingredient, contributing flavor, body, and sweetness. Different malts offer varying levels of sweetness and complexity.

- Hops: Add bitterness, flavor, and aroma. The type and quantity of hops vary by style, influencing everything from IPAs to stouts.

- Yeast: Essential for fermentation. Different yeast strains produce unique flavors and aromas, from fruity to earthy profiles. Clean fermentation is crucial for a well-balanced beer.

- Water: Pure, soft water is ideal, as hard water can affect the finish. Water also plays a role in extracting flavors from malt and hops during the boil.

- Brewing Techniques :

- Mashing: Breaking down starches in malt to convert sugars. Proper temperature control during mashing affects the final beer’s body and flavor.

- Boiling: Extracts flavors and aromas from hops while reducing bitterness over time. A vigorous boil can enhance hop utilization.

- Fermentation: Yeast converts sugar into alcohol and carbon dioxide, creating the beer’s characteristic fizz. Temperature control during fermentation impacts flavor development.

- Aging (Conditioning): Allows flavors to meld and gases to dissipate. Lagers often age longer to develop a cleaner taste.

- Beer Styles :

- Ale: Fermented at warmer temperatures, resulting in faster production and fruitier notes. Examples include IPAs and porters.

- Lager: Fermented at cooler temperatures for a smoother, cleaner taste. Popular styles include Helles and Pilsner.

- Stout: Robust and rich, often featuring roasted coffee-like flavors. Varieties include milk stouts and imperial stouts.

- Wheat Beers: Light and hazy, often with citrusy notes. Hefeweizen and witbier are classic examples.

- Serving Suggestions :

- Temperature: Serve most beers around 45-55°F (7-13°C) to optimize flavor and aroma. Exceptions include wheat beers, which can be slightly colder.

- Glassware: Use appropriate glass shapes, such as tulip glasses for ales and pilsners, to retain aroma and appearance.

By mastering these principles, brewers can craft beers that delight the senses and satisfy the palate. Experimentation and attention to detail are key to creating a truly exceptional beer.

0 Comments