Beer systems are the backbone of any successful brewing operation, whether you’re a home brewer looking to elevate your craft or a commercial brewery aiming to scale production. With the right beer system in place, you can optimize efficiency, maintain consistency, and deliver high-quality beverages to your audience. In this comprehensive guide, we’ll explore the best beer systems available, factors to consider when selecting the perfect setup for your needs, and how to maintain and care for your equipment to ensure peak performance. From budget-friendly options for home brewers to robust solutions for commercial breweries, this article will provide insights into the latest innovations and sustainable practices shaping the industry. Join us as we dive into the world of beer systems, where quality meets functionality, and every pour tells a story.

Key Takeaways

– Match Your Beer System to Your Scale: Whether you’re a home brewer or running a commercial brewery, choose a system that aligns with your production volume to maximize efficiency and cost-effectiveness.

– Consider Your Beer Style: Ensure your system can handle the specific temperature and fermentation requirements of your preferred beer types.

– Invest in Cost-Effective Solutions: Balance budget constraints with modular systems that allow for future expansion without breaking the bank.

– Prioritize Ease of Use and Maintenance: Opt for systems with intuitive controls and durable components to minimize downtime and ensure smooth operations.

– Opt for Scalable Designs: Choose modular systems that can adapt to growing production demands, preventing the need for frequent overhauls.

– Enhance Energy Efficiency: Select systems with efficient heating and cooling mechanisms to save energy costs and contribute to environmental sustainability.

– Ensure Reliable Support: Always go for vendors offering dependable customer support and access to spare parts to address issues quickly.

– Tailor to Local Conditions: Consider your geographical location and climate when selecting a system to ensure optimal performance in various environments.

These insights will help you select the right beer system, whether you’re a home brewer or managing a commercial brewery, ensuring efficiency, reliability, and scalability for years to come.

Best Beer Systems for Home Brewers and Commercial Breweries

When it comes to selecting the right beer systems, whether for home brewing or commercial use, it’s essential to choose equipment that balances quality, efficiency, and scalability. Here’s a breakdown of the top beer systems available:

- Home Brewing Equipment:

- Brew Pots: These come in various sizes, from 5-gallon to 50-gallon capacities, depending on the batch size. Stainless steel pots are preferred for durability and ease of cleaning.

- Mash Tuns: Essential for mashing, these can be single vessel or three-vessel designs. A three-vessel setup allows for better separation of wort andwort.

- Fermentation Tanks: Available in conical or cylindrical shapes, these tanks are typically made of food-grade plastic or stainless steel. Size options range from 5 gallons to 100 gallons.

- Kegging Systems: For smaller batches, a compact kegging system is ideal. These systems allow for easy storage and serving of beer.

- Commercial Brewery Equipment:

- Larger Fermenters: Commercial breweries often use 500-liter to 1000-liter conical fermenters for large-scale production. These are typically made of stainless steel for longevity and hygiene.

- Bottling Machines: High-speed bottling machines are a must for commercial operations, capable of bottling hundreds of bottles per minute. These can be fully automated or semi-automatic.

- Cask or Barrel Aging Systems: For craft breweries focusing on barrel-aged beers, cask aging systems are essential. These systems allow for controlled aging and offer flexibility in storage solutions.

- Water Treatment Systems: Pure water is critical for brewing. Commercial breweries often use reverse osmosis systems to ensure water quality meets standards.

- Key Considerations:

- Energy Efficiency: Look for systems with energy-efficient heating elements and insulation to reduce operational costs.

- Space Optimization: Compact designs are crucial for both home and commercial setups, especially in limited spaces.

- Customization: Many breweries prefer customizable systems to suit their specific needs, whether it’s a small batch setup or a large-scale operation.

- Third-Party Tools and Software:

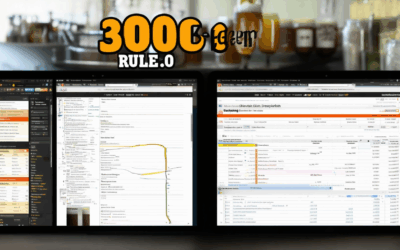

- Brewery Management Software: Tools like The Goods On Tap provide comprehensive solutions for tracking ingredients, monitoring fermentation, and managing production schedules.

- Quality Control Systems: Implementing systems for consistent quality ensures that every batch meets high standards, whether for home use or commercial release.

Best Beer Systems for Home Brewers and Commercial Breweries

When it comes to selecting the right beer systems, whether for home brewing or commercial use, it’s essential to choose equipment that balances quality, efficiency, and scalability. Here’s a breakdown of the top beer systems available:

- Home Brewing Equipment:

- Brew Pots: These come in various sizes, from 5-gallon to 50-gallon capacities, depending on the batch size. Stainless steel pots are preferred for durability and ease of cleaning.

- Mash Tuns: Essential for mashing, these can be single vessel or three-vessel designs. A three-vessel setup allows for better separation of wort andwort.

- Fermentation Tanks: Available in conical or cylindrical shapes, these tanks are typically made of food-grade plastic or stainless steel. Size options range from 5 gallons to 100 gallons.

- Kegging Systems: For smaller batches, a compact kegging system is ideal. These systems allow for easy storage and serving of beer.

- Commercial Brewery Equipment:

- Larger Fermenters: Commercial breweries often use 500-liter to 1000-liter conical fermenters for large-scale production. These are typically made of stainless steel for longevity and hygiene.

- Bottling Machines: High-speed bottling machines are a must for commercial operations, capable of bottling hundreds of bottles per minute. These can be fully automated or semi-automatic.

- Cask or Barrel Aging Systems: For craft breweries focusing on barrel-aged beers, cask aging systems are essential. These systems allow for controlled aging and offer flexibility in storage solutions.

- Water Treatment Systems: Pure water is critical for brewing. Commercial breweries often use reverse osmosis systems to ensure water quality meets standards.

- Key Considerations:

- Energy Efficiency: Look for systems with energy-efficient heating elements and insulation to reduce operational costs.

- Space Optimization: Compact designs are crucial for both home and commercial setups, especially in limited spaces.

- Customization: Many breweries prefer customizable systems to suit their specific needs, whether it’s a small batch setup or a large-scale operation.

- Third-Party Tools and Software:

- Brewery Management Software: Tools like The Goods On Tap provide comprehensive solutions for tracking ingredients, monitoring fermentation, and managing production schedules.

- Quality Control Systems: Implementing systems for consistent quality ensures that every batch meets high standards, whether for home use or commercial release.

Best Beer Systems for Home Brewers and Commercial Breweries

When it comes to selecting the right beer systems, whether for home brewing or commercial use, it’s essential to choose equipment that balances quality, efficiency, and scalability. Here’s a breakdown of the top beer systems available:

- Home Brewing Equipment:

- Brew Pots: These come in various sizes, from 5-gallon to 50-gallon capacities, depending on the batch size. Stainless steel pots are preferred for durability and ease of cleaning.

- Mash Tuns: Essential for mashing, these can be single vessel or three-vessel designs. A three-vessel setup allows for better separation of wort andwort.

- Fermentation Tanks: Available in conical or cylindrical shapes, these tanks are typically made of food-grade plastic or stainless steel. Size options range from 5 gallons to 100 gallons.

- Kegging Systems: For smaller batches, a compact kegging system is ideal. These systems allow for easy storage and serving of beer.

- Commercial Brewery Equipment:

- Larger Fermenters: Commercial breweries often use 500-liter to 1000-liter conical fermenters for large-scale production. These are typically made of stainless steel for longevity and hygiene.

- Bottling Machines: High-speed bottling machines are a must for commercial operations, capable of bottling hundreds of bottles per minute. These can be fully automated or semi-automatic.

- Cask or Barrel Aging Systems: For craft breweries focusing on barrel-aged beers, cask aging systems are essential. These systems allow for controlled aging and offer flexibility in storage solutions.

- Water Treatment Systems: Pure water is critical for brewing. Commercial breweries often use reverse osmosis systems to ensure water quality meets standards.

- Key Considerations:

- Energy Efficiency: Look for systems with energy-efficient heating elements and insulation to reduce operational costs.

- Space Optimization: Compact designs are crucial for both home and commercial setups, especially in limited spaces.

- Customization: Many breweries prefer customizable systems to suit their specific needs, whether it’s a small batch setup or a large-scale operation.

- Third-Party Tools and Software:

- Brewery Management Software: Tools like The Goods On Tap provide comprehensive solutions for tracking ingredients, monitoring fermentation, and managing production schedules.

- Quality Control Systems: Implementing systems for consistent quality ensures that every batch meets high standards, whether for home use or commercial release.

Factors to Consider When Choosing the Right Beer System

When selecting the ideal beer system for your needs, several key factors come into play:

- System Size

- Determine the production scale: Are you brewing for personal use, a small bar, or a large-scale operation? Choose a system that matches your volume requirements to optimize efficiency and cost-effectiveness.

-

Beer Type

- Consider the style of beer you aim to produce. Different beer types require varying temperatures and fermentation durations. Ensure the system can maintain the necessary conditions for your preferred beer styles.

-

Budget

- Assess your financial constraints. While a high-end system may offer advanced features, there are cost-effective options that deliver reliable performance. Look for modular systems that allow for future expansions without significant investments.

-

Maintenance and Ease of Use

- Opt for a system with intuitive controls and accessible components. Easy maintenance reduces downtime and ensures consistent performance. Prioritize systems with robust construction and simple repair processes.

-

Scalability for Future Growth

- Choose a system that can adapt to increased production demands. Modular designs allow for easy upgrades, preventing the need for a complete system overhaul as your needs evolve.

-

Energy Efficiency

- Energy costs can accumulate, so select a system with efficient mechanisms for heating and cooling. This not only saves money but also contributes positively to environmental sustainability.

-

Support and Service Availability

- Ensure access to reliable customer support and spare parts. A trustworthy vendor offering prompt assistance can mitigate issues swiftly, minimizing disruptions to your operations.

-

Location and Climate

- Consider your geographical location. Environmental factors like temperature extremes can impact system performance. Opt for solutions tailored to your local conditions to enhance reliability.

By thoughtfully evaluating these factors, you can select a beer system that aligns perfectly with your objectives, ensuring efficiency, reliability, and scalability for years to come.

Factors to Consider When Choosing the Right Beer System

When selecting the ideal beer system for your needs, several key factors come into play:

- System Size

- Determine the production scale: Are you brewing for personal use, a small bar, or a large-scale operation? Choose a system that matches your volume requirements to optimize efficiency and cost-effectiveness.

-

Beer Type

- Consider the style of beer you aim to produce. Different beer types require varying temperatures and fermentation durations. Ensure the system can maintain the necessary conditions for your preferred beer styles.

-

Budget

- Assess your financial constraints. While a high-end system may offer advanced features, there are cost-effective options that deliver reliable performance. Look for modular systems that allow for future expansions without significant investments.

-

Maintenance and Ease of Use

- Opt for a system with intuitive controls and accessible components. Easy maintenance reduces downtime and ensures consistent performance. Prioritize systems with robust construction and simple repair processes.

-

Scalability for Future Growth

- Choose a system that can adapt to increased production demands. Modular designs allow for easy upgrades, preventing the need for a complete system overhaul as your needs evolve.

-

Energy Efficiency

- Energy costs can accumulate, so select a system with efficient mechanisms for heating and cooling. This not only saves money but also contributes positively to environmental sustainability.

-

Support and Service Availability

- Ensure access to reliable customer support and spare parts. A trustworthy vendor offering prompt assistance can mitigate issues swiftly, minimizing disruptions to your operations.

-

Location and Climate

- Consider your geographical location. Environmental factors like temperature extremes can impact system performance. Opt for solutions tailored to your local conditions to enhance reliability.

By thoughtfully evaluating these factors, you can select a beer system that aligns perfectly with your objectives, ensuring efficiency, reliability, and scalability for years to come.

Best Beer Systems for Home Brewers and Commercial Breweries

When it comes to crafting the perfect beer, having the right system in place is crucial whether you’re a home brewer or running a commercial brewery. Here’s a breakdown of the top beer systems available:

- Home Brewing Systems

- All-in-one brewhouse systems: These compact units combine brewing, fermentation, and conditioning in one space, making them ideal for small-scale operations.

- Modular brewing setups: Perfect for those who want flexibility, these systems allow for separate tanks for malt, hops, water, and yeast, enabling precise control during the brewing process.

- D.I.Y. (Do-It-Yourself) kits: Great for hobbyists, these entry-level systems often come with everything needed to start brewing, including instructions and sometimes even video tutorials.

- Commercial Brewery Equipment

- Larger-scale brewhouses: Designed for high-volume production, these systems can handle everything from malt milling to lautering in a single unit, optimizing efficiency.

- Fermation tanks: These are critical for controlling the temperature and environment during fermentation, ensuring consistent flavor profiles in every batch.

- Bottling and packaging lines: Once the beer is ready, efficient bottling or canning systems are essential for meeting demand without compromising quality.

- Capacity: Choose a system that matches your expected production volume.

- Ease of Use: Look for user-friendly controls and intuitive designs to minimize downtime.

- Customization: Many systems offer upgrades and modifications to suit specific preferences or growing needs.

- Maintenance: Opt for systems with easy-to-clean components to reduce downtime and maintenance costs.

- Scalability: Ensure the system can grow with your business, whether you’re expanding production or experimenting with new recipes.

Key Considerations

When selecting a beer system, consider:

For more details on these systems and to explore the latest trends in brewing technology, visit our comprehensive guide on beer systems .

Conclusion

The right beer system is crucial for achieving consistency and maximizing efficiency, whether you’re brewing at home or at a commercial scale. By focusing on capacity, ease of use, and long-term scalability, you can ensure your brewery meets its full potential.

0 Comments